Your cart is currently empty!

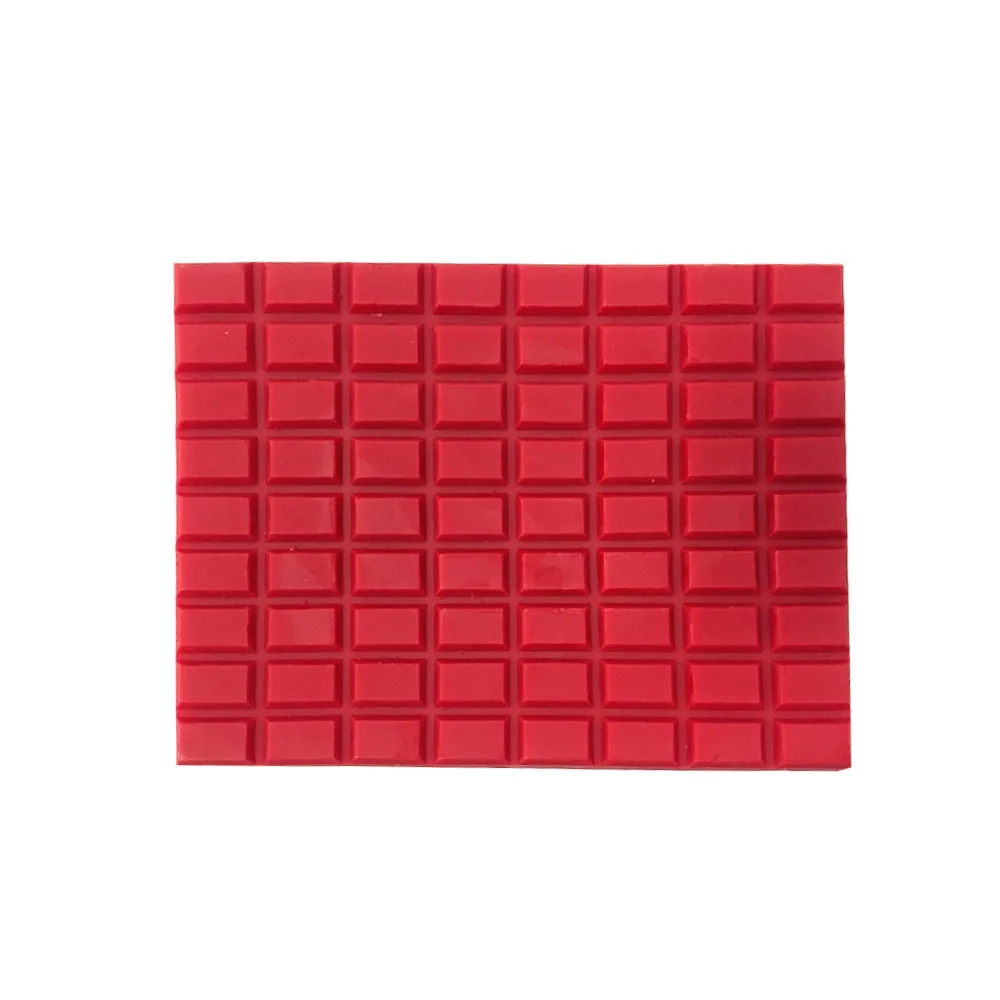

Hard Wax Ear Impression Wax Paraffin Dipping Wax Refine and Smooth Ear Impressions for DIY Custom Earmolds and IEMs 500g

Size: 500 g Model Number: A100601-003 Material: Polishing paste Brand Name: SoundLink Origin: Mainland China Item Type: ear care Item Name: Ear impression wax Color: Red Net weight: 500 g Function characteristics: Quick, non-toxic Hard Wax Ear Impression Wax Paraffin Dipping Wax Refine and Smooth Ear Impressions for DIY Custom Earmolds and IEMs 500g Net weight: 500g Wax size: 16.5*13*1.5 cm (3pcs) Melting point: 50 […]

232 in stock

Description

- Size: 500 g

- Model Number: A100601-003

- Material: Polishing paste

- Brand Name: SoundLink

- Origin: Mainland China

- Item Type: ear care

- Item Name: Ear impression wax

- Color: Red

- Net weight: 500 g

- Function characteristics: Quick, non-toxic

Hard Wax Ear Impression Wax Paraffin Dipping Wax Refine and Smooth Ear Impressions for DIY Custom Earmolds and IEMs 500g

Net weight: 500g

Wax size: 16.5*13*1.5 cm (3pcs)

Melting point: 50 ℃

Working temperature: Constant 80-82 ℃

Wax is used to coat your silicone impressions so that you’ll get a smooth surface. Paraffin dipping wax smoothes all bumps of the ear impression.

Perfect preparation for the use of the duplicating material

You can also fill any potential holes in your impression with a toothpick and then molten wax.

Before you dip the impressions into the wax, only do one dip or you risk that you have to grind off a lot of the shell to get a good fit.

If you don’t have a professional wax melter, here are some tips

1, A clean can to melt the wax in

2, It needs to be put flat on the Cooktop. If you have an Induction Cooktop you’ll need a magnetic can for it to work and only do it on low heat, it needs to melt not cook.

3, To avoid bubbles and drops, we need to refine the impressions before dipping wax

4, Recommended temperature for dipping impressions is constant 80 ℃-82 ℃, so a professional wax melter with thermostatic control of temperature is really necessary

5, Control the thickness by experiences. Practice more, you will know what temperature, and how long time is good for dipping the impressions

6, If you are customizing hearing aid shells for a people who have serious hearing loss, in order to get better airtightness, better cover thicker wax on the impressions

7, If you are DIY custom in-ear monitors, the purpose of dipping impressions in wax is just to smooth out the impressions. So a thinner cover will be ok, otherwise, the finished shells are hurting ears.

Related products

-

1Pair Ear Impression Silicone Dosing Spoon for Taking Appropriate Impression Putty Material

8.04$ -

400g*2 ABR Ear Impression Material Silicone for Custom Hearing Aids Earmolds DIY IEM Earphones

165.19$ -

50pcs Silicone Material Mixing Tube Tip PP Material

84.67$ -

ABR Ear Impression Material Silicone for Custom Hearing Aids Earmolds DIY IEM Earphones 700g*2

255.19$ -

ABR Ear Impression Material Silicone Putty for Custom Hearing Aids Earmolds DIY IEM Earphones 800g*2

244.51$

Reviews

There are no reviews yet.